X-ray Diffraction Analysis (XRD)

Determination of the quantitative mineral composition of a powder sample

X-ray diffraction analysis of powder samples is the most effective and precise analytical method for determining the quantitative mineral composition of a multi-mineral sample. The method is based on the Nobel Prize-winning discovery of the diffraction of X-rays at the so-called "lattice planes" of crystals (Max von Laue, 1914). Physically, there is a relationship between the wavelength "λ" of the radiation used (e.g. copper anode with λCu = 1.54 Å), the lattice plane spacing "d" of a crystalline material and the diffraction angle "θ" (Bagg's equation). Analytically, this physical relationship forms the basis for the measurement of mineral-containing powder samples in X-ray diffractometers. The collected data are visualised and evaluated in an X-ray diffractogram, where the expertise of the user plays the decisive role. In the past century, the technology of the measurement method as well as the numerical basis of the evaluation (Rietveld refinement) has been continuously developed, but the evaluation of the diffractograms is still done manually.

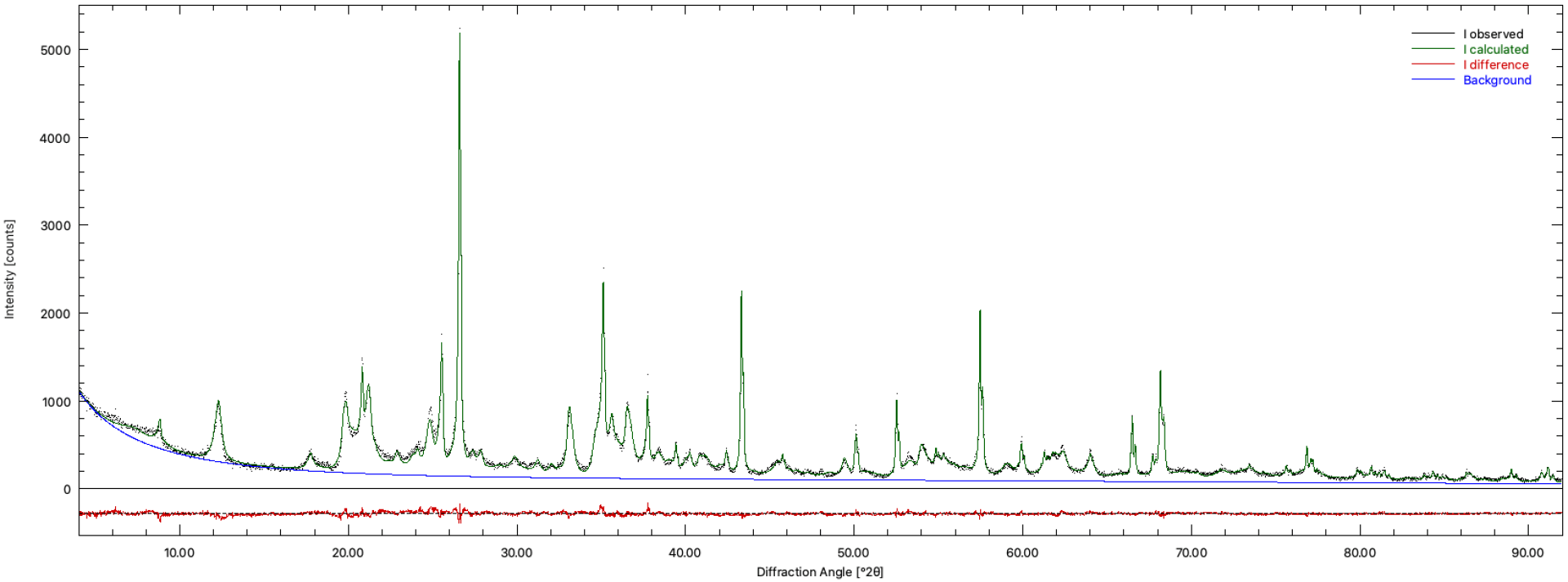

Figure 1: Diffractogram of a sample with a high clay content. In black the measured data points (observed), in green the numerically calculated diffractogram (calculated) by using various mineral structure models and in red the difference between the two diffractograms (difference, ideally a straight line). The sample shows the following mineral content (values in % by mass):

- Sandy components: quartz (12.9 %)

- Clay minerals: mixed-layers of illite-smectite (54.7 %) and kaolinite (18.4 %)

- Heavy minerals: anatase (1.2 %) and rutile (1.4 %)

- Iron oxides and -hydroxides: hematite (4.0 %) and goethite (7.4 %)

Applications

X-ray diffraction analysis is used to identify and quantify mineral components in a variety of industries:

Energy and mining industry:

- Characterisation of natural rocks and classification of the lithotype, e.g. in natural oil & gas exploration.

- Determination of mineral grades in the exploration of potential ore and clay deposits

- Investigations of the individual components of sediments and soils

- Characterisation of fly ashes and slags from the combustion of lignite

- Classification of lignites into quality classes for combustion

Infrastructure and building materials industry:

- Determination of the wear and bonding tendency of rocks for drilling tools in tunnel construction

- Quantification of critical mineral components in construction projects such as smectite and anhydrite

- Characterisation of the purity of raw materials such as limestones

- Quality assurance in the production of cement and gypsum

- Classification of building and filling materials, e.g. in the deconstruction of buildings